How CIC is used in the Food Processing Industry

Block Radiant Heat

Food plants started using insulation coating on food cooking equipment and now save upwards of 25% of their natural gas cost. This “solution” has been around for almost 25 years, having been invented by Mr. Al Beatty of a company named “Envirotrol”. It’s basically latex paint with most of the Titanium Dioxide and Calcium Carbonate removed and replaced with hollow ceramic microbeads. The tight layers of microbeads block radiant heat transfer, roughly the way that “Low-E” oxide coatings block infra-red radiation on windows. Historically, this technology has often been regarded by many as snake oil, based mainly on exaggerated claims of much greater energy efficiency.

Resists Caustic Sterilization and fire Hose Rinsing

This insulation material does not rely on the same characteristics as traditional mass-based insulation materials. Ceramic insulation coating (CIC) blocks a percentage of heat transferred by resisting or blocking mostly infrared-based radiation heat transfer. Traditional mass-based materials slow down heat transfer using “conductive” resistance. Both materials have strengths and weaknesses. The key is to use them based on strengths and avoid their use where weaknesses prevail

Applied in Thin Layers

When ceramic insulation coating (CIC) is applied in thin layers (12 mils or 300 microns x 2 coats) and allowed to dry thoroughly for a few hours, there’s also thin air gaps between layers that resist conductive heat transfer. That value has been measured at 0.1176 W/mK on ACS CIC.

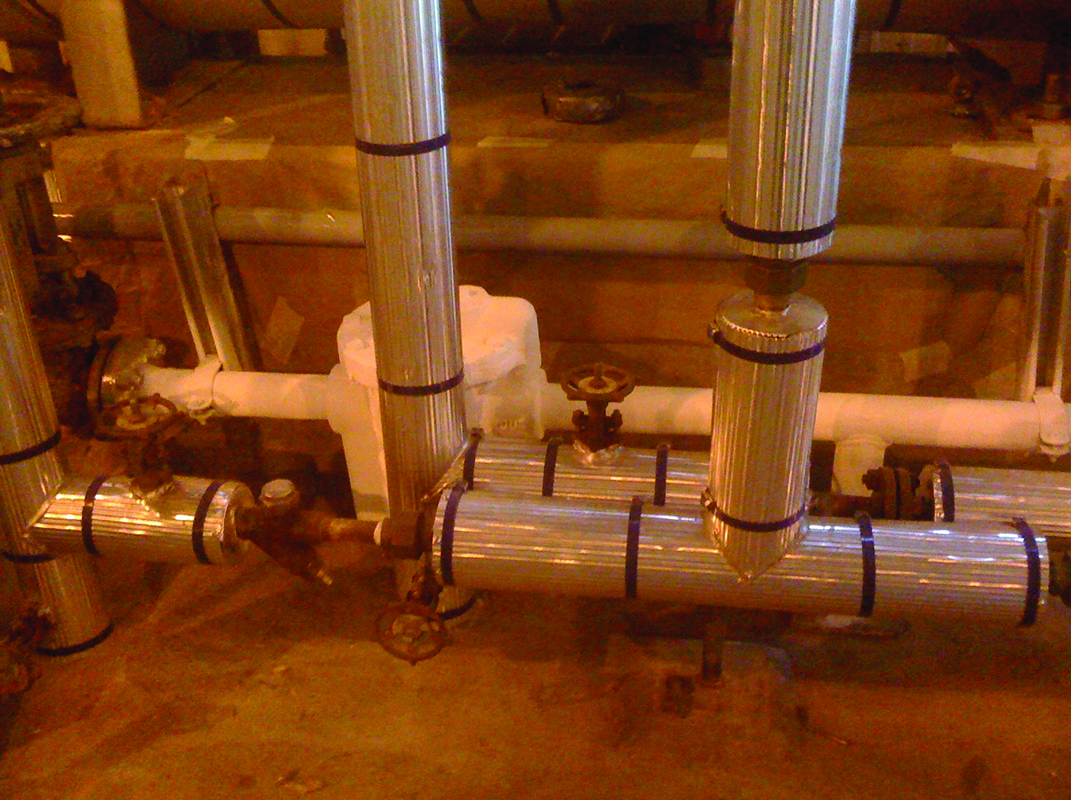

When this coating is applied on saturated steam equipment (pipes, valves, canning shells, tanks, etc.), there’s a dense set of layers that are shown to block 25% or more heat.

2 mm or 80 mils is best for steam applications

Most CIC saturated steam applications use around 2mm/80 mils for best performance in the 220F/100C range. Higher temperatures may benefit with 2.5 to 3mm/100-120 mils. But after a certain point, each additional layer of CIC becomes an incremental contribution to blocking heat. Traditional materials also lose efficiency with greater thickness. So, it’s no surprise that CIC works the same way. What is surprising is that U value calculations appear to assign a linear thermal resistance value based on thickness. What’s also interesting is that many people do not take into account what happens when moisture content is factored into conductive efficiency.

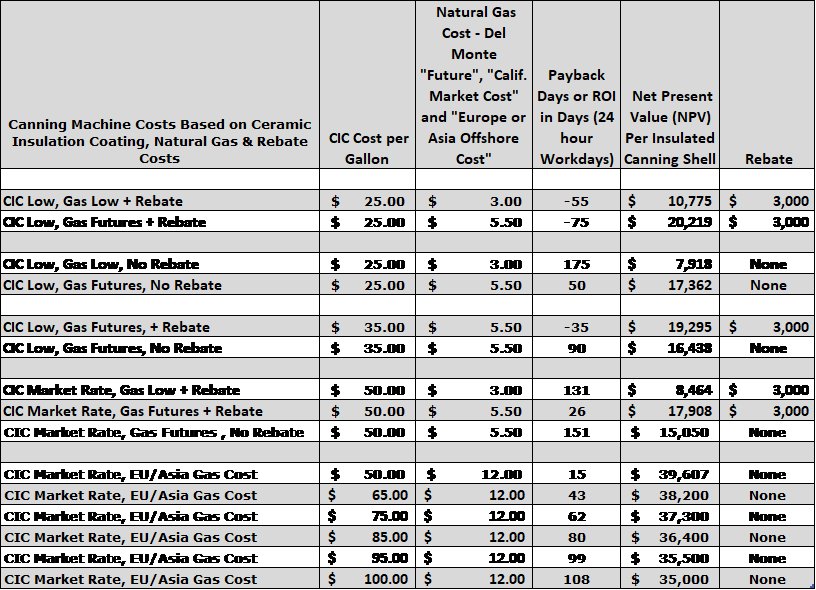

Rebates

What’s also helping is that Pacific Gas & Electric and SoCal Edison, California’s two energy suppliers are paying energy rebates to plants using CIC. The utilities are paying $1.00 per Therm saved. That works out to about $3,000 per average canning shell running at 200F. The net result is a payback period as soon as the equipment is operating. Even without the rebate, the ROI is around 130 days of operation

25% Energy Efficiency

The 25% energy efficiency was determined by Del Monte Foods energy engineer, Mr. Bill Riker. Mr. Riker used two separate tests to determine an efficiency value. First he used “side-by-side” test based on coating 2 x 6″/150mm steel pipe. Efficiency was measured by placing a steam trap to remove condensate entering the two pipes and then adding a steam trap to the ends of each pipe to collect condensate for comparison of volume after cooling it with a water bath. The first test’s comparison showed a 24% volume difference. The second test was a “before and after” comparison of steam condensate volumes used to heat a canning machine shell up to 90-100C/200-212F. This test provided a 26% condensate volume difference. For efficient steam boilers, that meant about a 25% gas cost to convert condensate back to steam.

The ROI Payback Period is a straight forward calculation

Bill Riker created a cost model to determine a payback period (ROI), Therms saved and a Net Present Value (NPV) for saturated steam applications. That model is available on request. Users can verify variables and apply their own plant costs to determine their ROI. We’ve focused on generating realistic metrics based on real values. It’s a straightforward and simple story.